TEST BENCHES

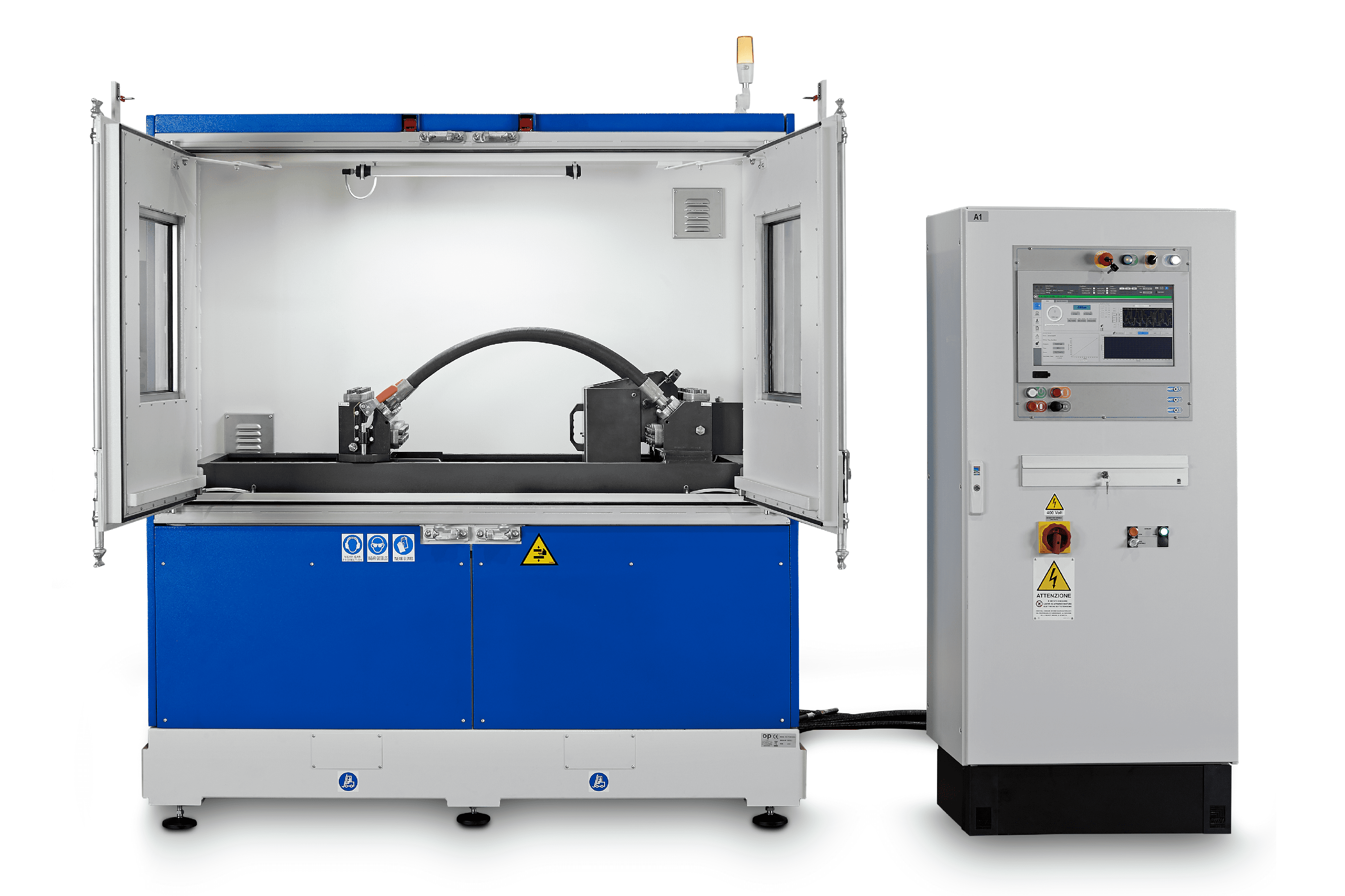

TSIP 700 NN

Flexible Rigid Hoses

The bench TSIP 700 NN performs impulse test pressure of hydraulic components, such as flexible hoses and rigid pipes, fittings, quick release couplings and valves according to SAE J343, ISO 6803, ISO 6605.

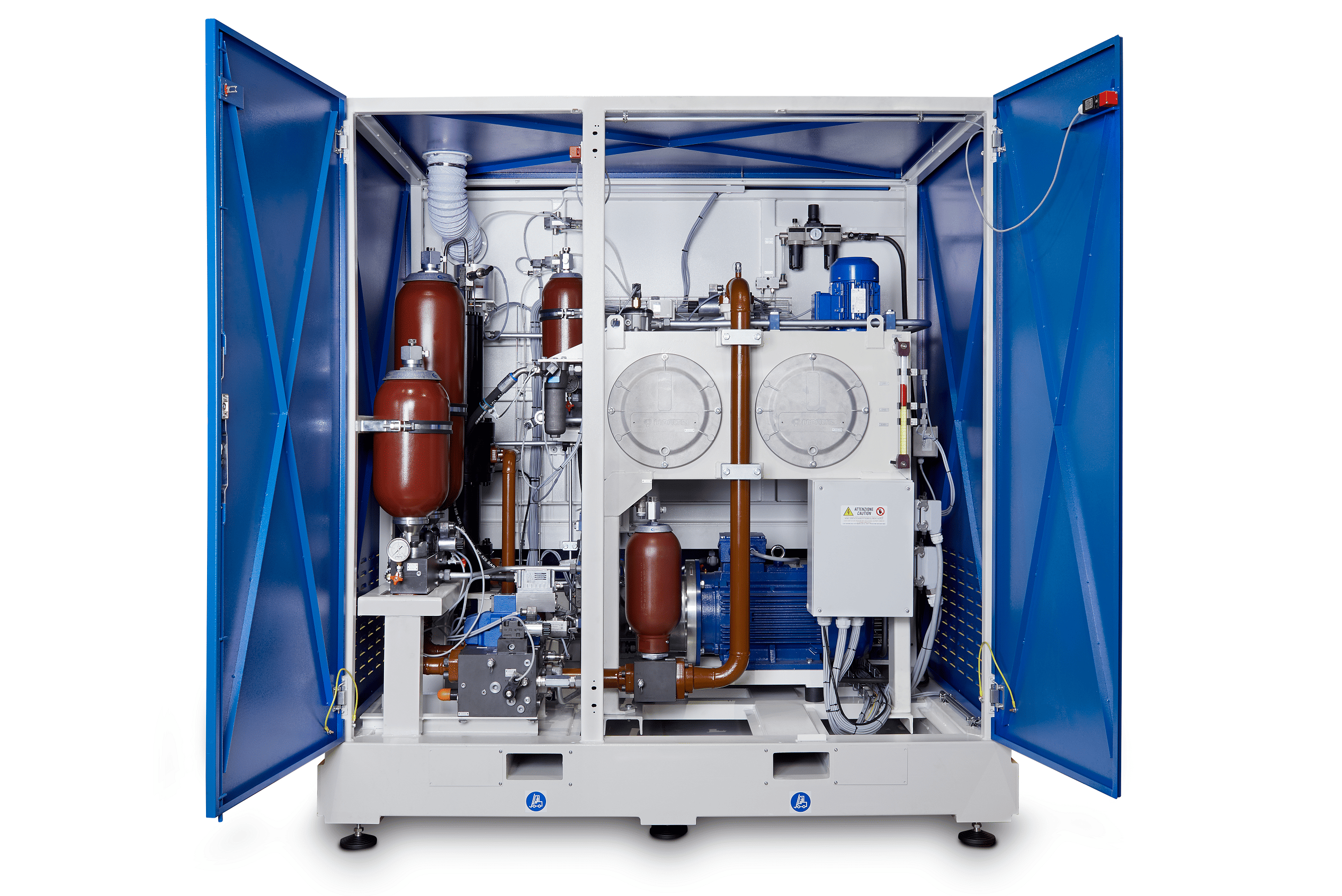

The bench is composed of:

• Hydraulic system with main tank, hydraulic power pack and auxiliary tank for the control system of the test fluid temperature;

• Electrical system with IP55 protection rating in compliance with EN60529;

• Industrial PLC with 19’’ touch screen, integrated in the structure.

TECHNICAL DATA

• Pressure wave impulse according to SAE J343, ISO 6803, ISO 6605

• Maximum test pressure 700 bar (10150 Psi)

• Minimum test pressure 50 bar (725 Psi)

• Displacement per impulse 330 cm3(20 inch3)

• Maximum test frequency 1Hz

• Maximum oil temperature 150 °C (302°F)

• N° 2 manifolds, one of which manually selectable (by external handwheel) up to a distance of

1200 mm (47.24’’) with 24 1/2’’ connections positioned at 0°-45°-90° (MODIFIABLE ON DEMAND –OPTIONAL)

• Test according to SAE J343 standards

• N.1 hose of 2’’ 4SH or R15

• N.2 hoses of 1’’ 1/2 R15

• N. 4 hoses of 1’’ 4SH or R15

SAFETY

• Interlocks, which prevent starting the test when the hatch is open

• Displaying windows, which allow to see the elements being tested

• Complete with windows and metallic grid protections

• Emergency button

• Automatic stop in case of any bench malfunction

POWER SUPPLY

• Standard voltage 400 V – 50 Hz – threephase (different voltage on demand)

• Motor power of 30 kW

• Cooling industrial water T≤20°C

OPTIONAL

• REMOTE SUPPORT DEVICE, software system for failure detection, suitable for online remote support

• Fume extraction system and oil separator

• MOBILE CONTROL PANEL, Industrial PLC with 19’’ touch screen display on mobile support

• ADDITIONAL CENTRAL MANIFOLD, which in compliance with the bench specifications can test up to 12 small and medium hoses

• OIL MIST DETECTION SYSTEM, installed in the testing chamber