TEST BENCH

TSHF 300 NN

Automotive Filters

The TSHF 300 NN test bench performs automotive filter tests in compliance with the ISO3968 standards.

The test bench is divided into:

• Hydraulic system with tank that can be pressurised up to 4 bar, PED certified and provided with an independent oil heating system, allowing performing tests up to 150°C

• Electrical system with IP55 protection rating in compliance with EN60529

• Industrial PC with 17’’ touch screen, fixed by a mobile support

The automation of the test is carried out through a customized software, thus allowing setting a series of test data, displaying the graphic and numeric test trend, storing instructions and printing the final test report.The system is provided with an on-line remote assistance capable of detecting possible failures. The system is provided with an on-line remote assistance capable of detecting possible failures.

TECHNICAL DATA

• Maximum operating capacity 300 lt/min

• Minimum operating capacity 5 lt/min

• Maximum operating pressure 20 bar

• Maximum operating temperature 150°C

• Minimum operating temperature 30°

• Maximum operating viscosity 100 cst

• Minimum operating viscosity 2 cst

• Quick oil heating system

• Oil hermostat system in the main tank

• Auxiliary tank for waste oil recovery

• Filter thermostatic by-pass control

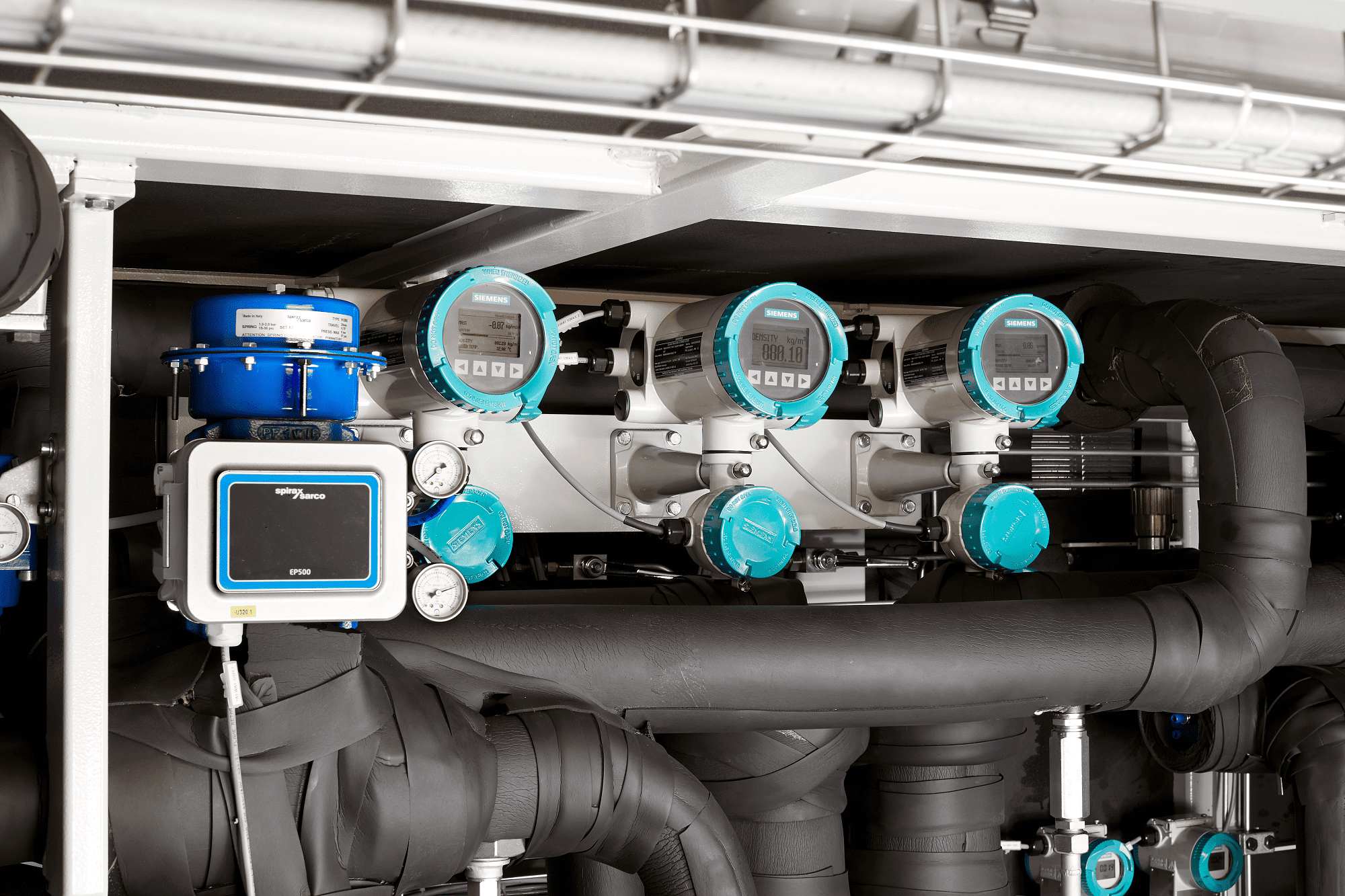

• Mass flow meters

• Automatic emptying and blowing of the circuit after the test

• Double manifold for smoke suction

• N.1 set of flexible hoses and DN 1”1/2 fitting for connecting the filter to be tested up to 300 lt/min

• N.1 set of flexible hoses and DN 1” fitting for connecting the filter to be tested up to 100 lt/min

• N.1 system for holding the filter to be tested complete with guides adjustable on 2 axes

SAFETY

• Electric interlock when performing the test with open door

• Openings in polycarbonate for displaying the elements being tested

• Emergency button

• Automatic interruption in case of any malfunction of the bench

POWER SUPPLY

• Standard voltage 400 V – 50 Hz – three-phase (different voltage on demand)

• Total installed power 24 kw

• Industrial cooling water T≤20°C

OPTIONAL

• SYSTEM FOR INTRODUCING, CONTROLLING AND MEASURING 2% CONTAMINATED WATER IN THE MAIN CIRCUIT

• COLOUR: outside structure RAL 7035 Customized colour on demand.

• REMOTE ONLINE SUPPORT – software system for failures detected and on-line remote support

• CONTROL PANEL – Industrial PC with 17” touch screen