TEST BENCHES

TSBP 500 NN

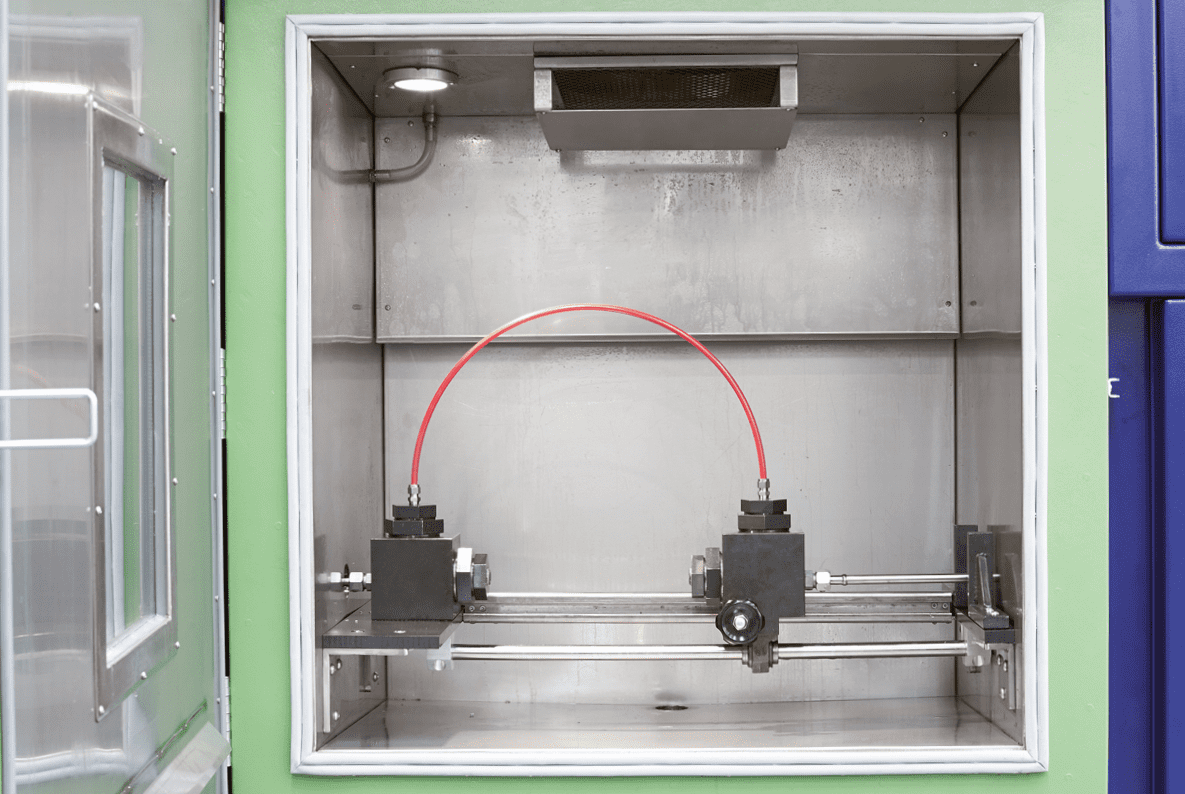

Thermoplastic Hoses

The test bench TSGP 500 NN makes burst test of thermoplastic tubing according to the following

specifications:

• ISO1402 – 7.3

• ISO 7628:2010 – 9.1

• SAE J844 9.9

• SAE J2044 ed. 09-2002 – 7.7

• VALEO 402352 ed. 09-2005 6.7.2

• VOLVO 31813157-008 ed.28-10-2010

• VOLVO 31813157-008 ed. 28-10-2010 3.3.6

TECHNICAL DATA

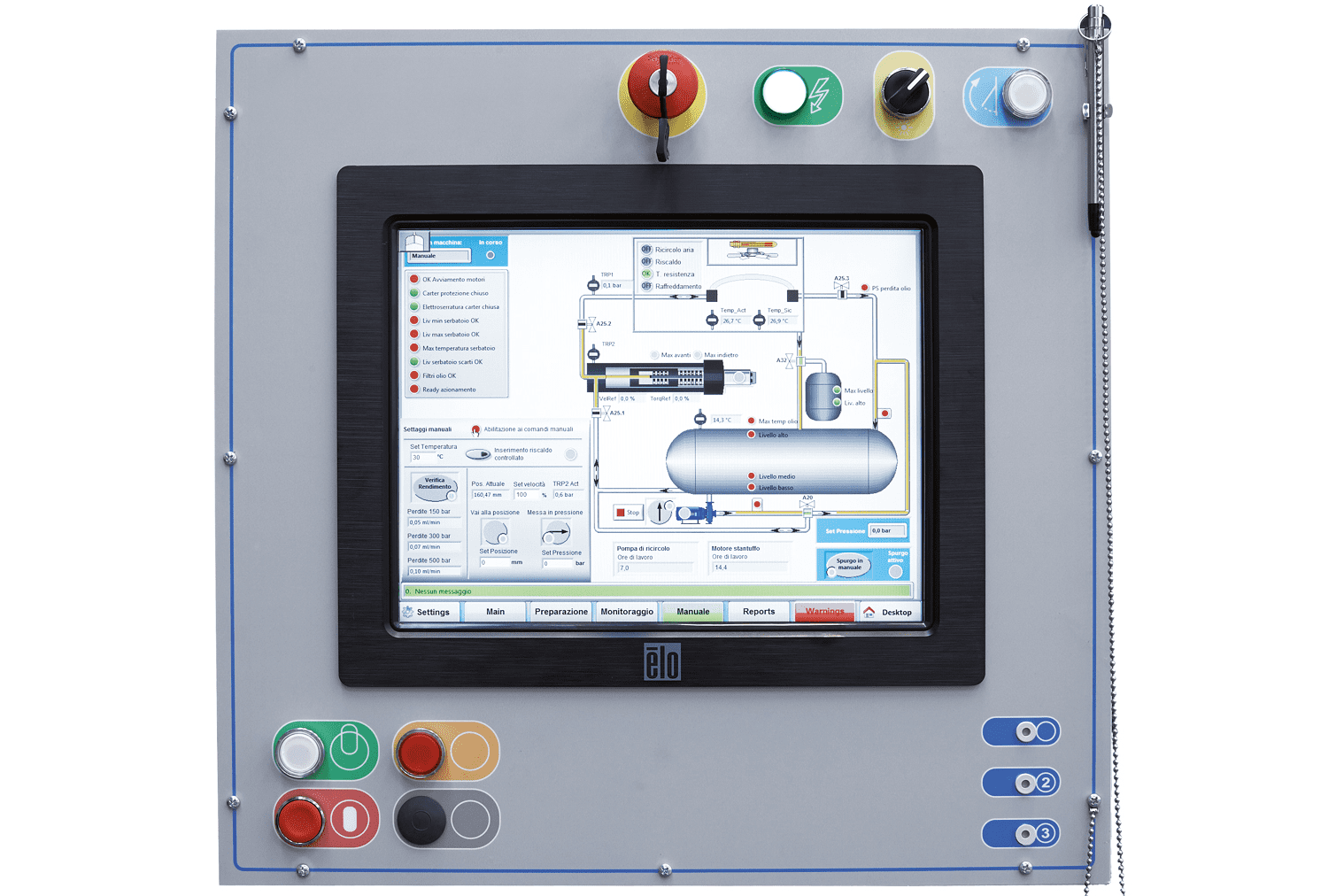

• Pressure control with high precision regulation

• Maximum test pressure: 500 bar

• Minimum test pressure: 10 bar

• Maximum quantity of hoses to be tested:1

• Maximum volume comprimibile: 350 cm3

• Testing chamber dimensions: 900x580x800 mm (LxWxH)

• Adjustable pressure levels: from 20 bar/min up to 400 bar/min

• Adjustable temperature levels: from 0 up to 10°C/h

• Temperature of the heating chamber during the test: from 20° to 180°C

• Temperature regulation precision: ±3°C

• Pressure regulation precision ±0,5 bar

• Possibility to work continuously 24 hours/per day; alarm system and automatic shutdown in case of any problem

• Total duration of the test 96+96h

• N.2 manifolds, one is mobile (0°-90°)

• N.2 connections for manifold 1”

• M.9 adaptors for manifold (G1/8” – G1/4” – M10x1 – M12x1.5 – M14x1.5– M16x1.5 – M18x1.5 – M22x1.5 – M26x1.5)

• Testing chamber in stainless steel

SAFETY

• Interlocks avoid to run test with open hatch

• Opening for displaying the elements being tested

• Emergency button

• Automatic interruption for any problem

POWER SUPPLY

• Standard voltage 400 V – 50 Hz – three-phase (different voltage on demand)

• Motor power of 6.3 kW

• Compressed air 7 bar

OPTIONAL

• REMOTE SUPPORT DEVICE (Software system for failured detected suitable for online remote support)

• SPECIAL ADAPTORS FOR MANIFOLDS